What is filterability?

The filterability of a liquid is its ability to be passed through one or a series of filters to provide a desired filtrate quality. The main factors affecting filterability are suspended solids and colloidal content. Some examples of suspended solids are crystals, minerals, microbiologiocal cells, general processing debris and disturbed sediment. Examples of colloidal content are polysaccharides, proteins and any long chain molecules, particularly those that will entangle or agglomerate.

Can haze tell us how filterable a liquid is?

As a rule of thumb, high haze (turbidity) will result in lower filterability (faster filter blockage). However, there is no true correlation between haze and filterability due to the wide range of components responsible for the haze and for blocking a filter. At IPTL we measure haze using light scatter at 90 degrees, which is more sensitive to colloids than large particles and is usually applied to the finished beer specifications. Casts and discrete individual particles can often be visible to the naked eye and can be defined objectively using shallower light scattering angles.

How do we measure filterability?

There are various measures of filterability, some of which are used in common practice (eg filterability index, silt density index, Vmax). IPTL will apply these standard methodologies if seen fit, but our preference is a more practical approach. To do this, we take a representative sample of the liquid to be filtered and pass it through a combination of filters whilst monitoring the amount of liquid passed with time. Additionally, we measure haze before and after filtration.

We use 25mm or 65mm diameter discs filters for filterability tests. Usually, the smaller discs represent filtration media that are contained within our cartridge filter products, while the larger ones represent our sheet and lenticular media. We can also use media from higher depth filter formats, for example bags, but these are usually best tested at pilot-scale. There's a list below of the common grades of media that we use.

How is the data presented and used?

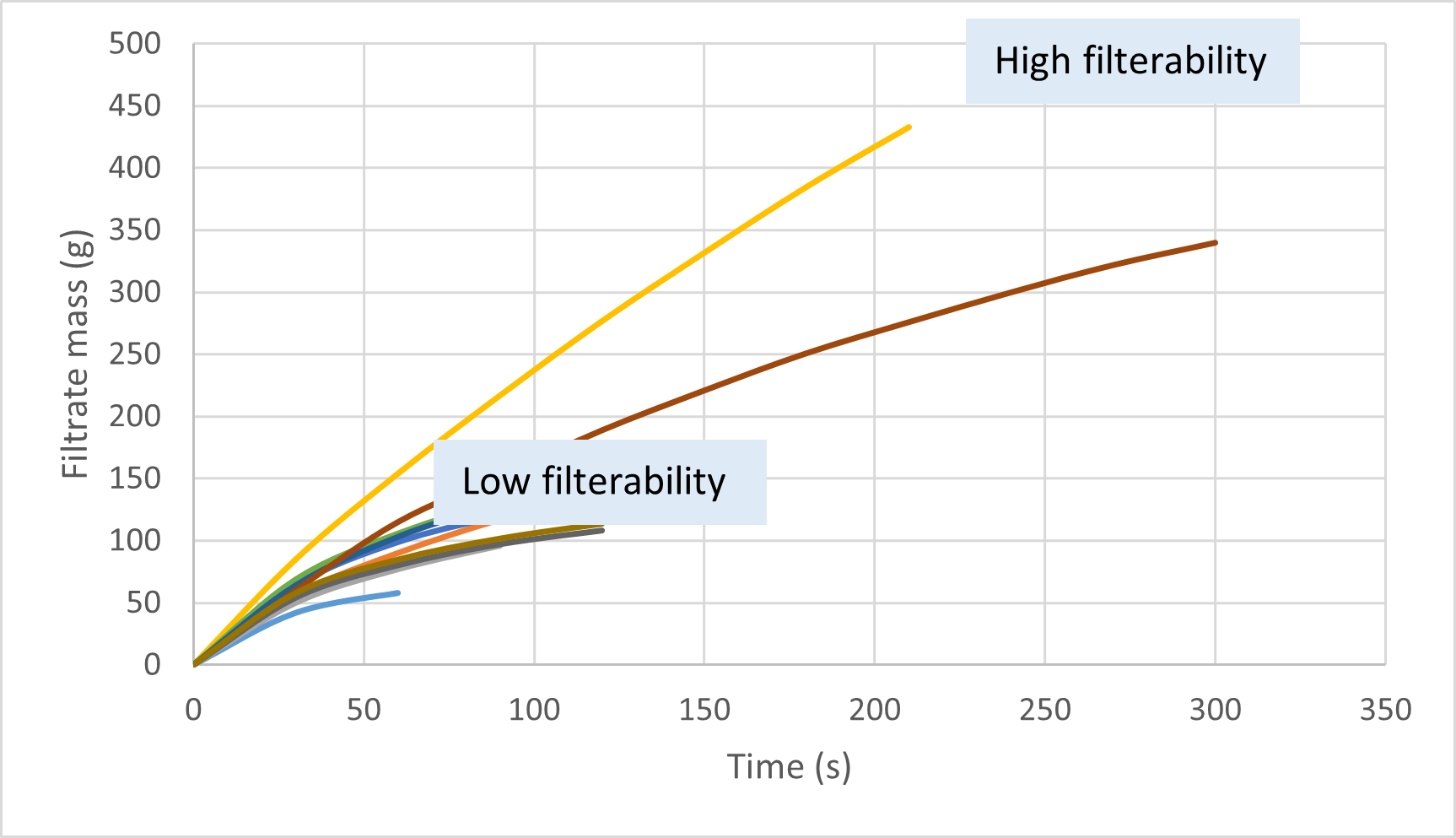

We report the obtained data in graphical form, which illustrates the flow curves during the course of testing. This gives good visual comparisons of how a single filter type can handle different liquids or how a single liquid filters through various media types. We also calculate Vmax, which is the maximum theoretical volume to blockage. This value can be scaled up from the surface area of the test disc to the surface area in a pilot- or full-scale system.

By comparing the obtained results, and sometimes with reference to the vast number of historical results obtained by the IPTL team, we can either narrow down the choices of filters for pilot- or full-scale operation or make suggestions about additional pre-treatment of the liquid to improve its filterability.

What limitations does the testing have?

The tests are not ideal for a few reasons. The flow rate per unit area of filter medium is usually much higher than would be seen in the full-scale process, which can affect the rate of blockage. The tests also assume continuous processing to blockage which is not an ideal scenario. Usually a filtration run would be stopped prior to full blockage occurring and the filters would be cleaned at end of day or between batches to extend their life. Finally, the tests can only provide a snapshot of filterability based on the specification of the supplied sample(s) at time of testing, so the results will not account for batch variability.

However, the results gained provide very good comparative performance data, especially when compared to the many years' worth of data experienced by the IPTL team, which then enables the number of choices for pilot-scale or full-scale filter selection to be narrowed down or provides a strategy to prepare the liquid more suitably for filtration.

Polypropylene pleated cartridge media

| Reference | Brand | Retention rating (micron) | Retention specification (%) |

|---|---|---|---|

| PPP-B | Parker | 0.6 | >99.98 particulate |

| PPP-D | Parker | 1 | >99.98 particulate |

| PHA-G | Parker | 3 | >99.98 particulate |

| PHA-H | Parker | 5 | >99.98 particulate |

| PHA-K | Parker | 10 | >99.98 particulate |

| PHA-L | Parker | 15 | >99.98 particulate |

| PHA-M | Parker | 20 | >99.98 particulate |

| PHA-N | Parker | 25 | >99.98 particulate |

| ZCPP-040 | Parker | 40 | >99.98 particulate |

| ZCPP-055 | Parker | 55 | >99.98 particulate |

| ZCPP-075 | Parker | 75 | >99.98 particulate |

| ZCPP-100 | Parker | 100 | >99.98 particulate |

| PPA006 | IPTL | 0.6 | >99.9 particulate |

| PPA01 | IPTL | 1 | >99.9 particulate |

| PPA05 | IPTL | 5 | >99.9 particulate |

| PPA10 | IPTL | 10 | >99.9 particulate |

| PPA25 | IPTL | 25 | >99.9 particulate |

| PPA50 | IPTL | 50 | >99.9 particulate |

New Paragraph

Borosilicate microfibre cartridge media

| Reference | Brand | Retention rating (micron) | Retention specification (%) |

|---|---|---|---|

| PGF-B | Parker | 0.6 | >99.98 particulate |

| PGF-D | Parker | 1 | >99.98 particulate |

| PGF-G | Parker | 3 | >99.98 particulate |

| PGF-H | Parker | 5 | >99.98 particulate |

| PGF-K | Parker | 10 | >99.98 particulate |

| PBA006 | IPTL | 0.6 | >99.9 particulate |

| PBA01 | IPTL | 1 | >99.9 particulate |

| PBA05 | IPTL | 5 | >99.9 particulate |

| PBA10 | IPTL | 10 | >99.9 particulate |

Polyethersulphone membrane cartridge media

| Reference | Brand | Retention rating (micron) | Retention specification (%) |

|---|---|---|---|

| BMS-02 | Parker | 0.2 | >99.99999 pharmaceutical |

| BMS-04 | Parker | 0.45 | >99.99999 pharmaceutical |

| BPS-04 | Parker | 0.45 | >99.99999 beverage |

| BPS-06 | Parker | 0.65 | >99.99999 beverage |

| BPS-08 | Parker | 0.8 | >99.99999 beverage |

| BPS-12 | Parker | 1.2 | >99.99999 beverage |

Sheet and lenticular module media

| Reference | Brand | Retention rating (micron) | Retention specification |

|---|---|---|---|

| XE05 (XE0005H) | Filtrox (Carlson) | 15 - 35 | Particulate |

| XE10 (XE0010H) | Filtrox (Carlson) | 10 - 30 | Particulate |

| XE14 (XE0020H) | Filtrox (Carlson) | 8 - 20 | Particulate |

| XE24 (XE0050H) | Filtrox (Carlson) | 6 - 15 | Particulate |

| XE34 (XE0090H) | Filtrox (Carlson) | 4 - 9 | Particulate |

| XE44 (XE0150H) | Filtrox (Carlson) | 3 - 6 | Particulate |

| XE64 (XE0200H) | Filtrox (Carlson) | 1.5 - 3 | Particulate |

| XE94 (XE0400H) | Filtrox (Carlson) | 0.6 - 1.5 | Particulate |

| XE104 (XE0675H) | Filtrox (Carlson) | 0.5 - 0,8 | Pre-stabilisation |

| AF120 | Filtrox | 0.4 - 0.7 | Pre-stabilisation |

| AF130 | Filtrox | 0.4 - 0.6 | Pre-stabilisation |

| AF140 | Filtrox | 0.2 - 0.4 | Pre-stabilisation |

| RW (PROC3AN) | Filtrox (Carlson) | Adsorption | Colour / odour reduction |